Making stainless requires adding 12 or more chromium. Stainless steel is an alloy that contains 105 or.

Due to its low carbon content most stainless steel is somewhat softer than carbon steel and thus has a fairly low yield strength.

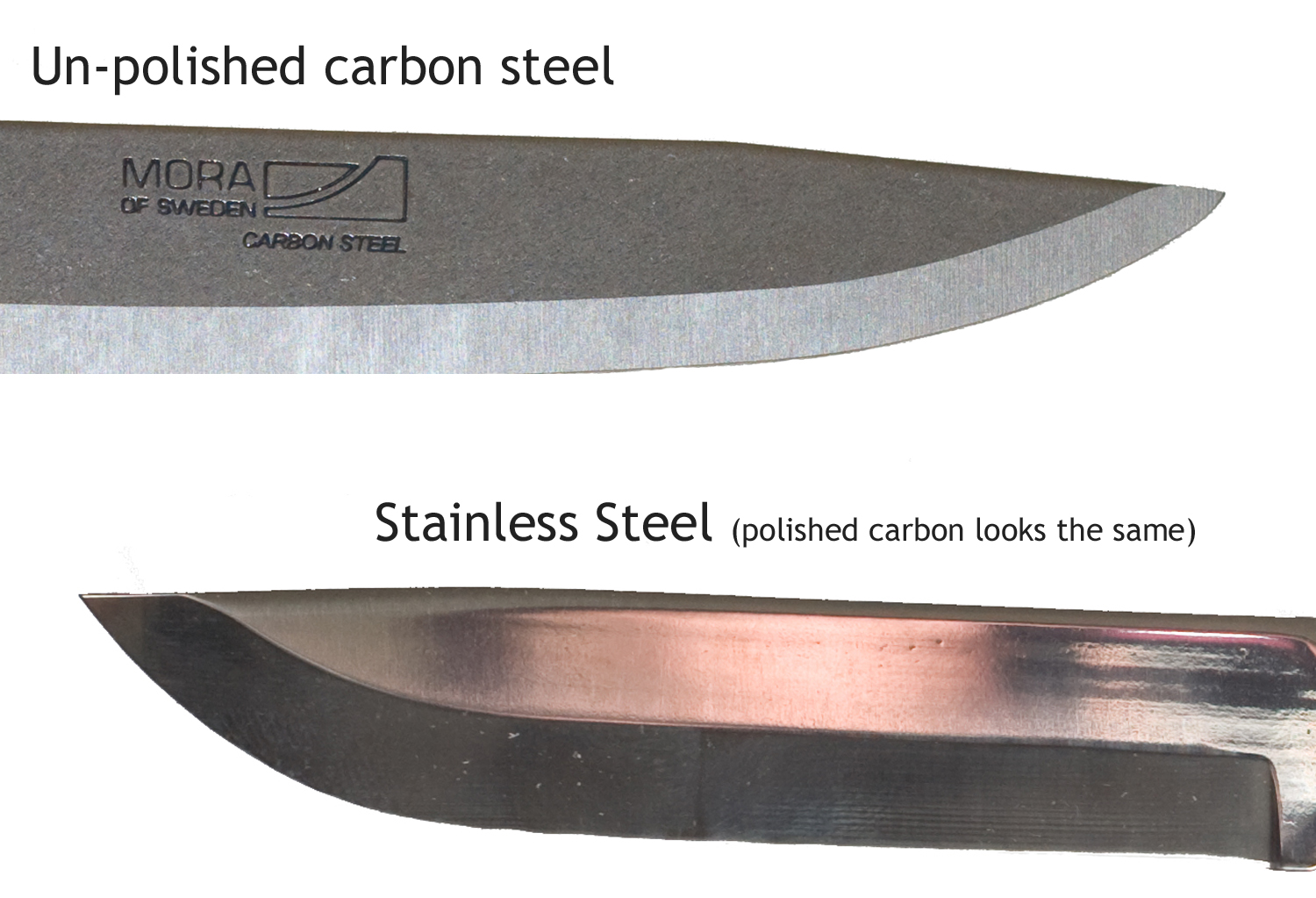

High carbon steel vs stainless. Stainless steel has a high chromium content which acts as a protective layer against corrosion and rust. Carbon steel is high in carbon that when exposed to moisture can corrode and rust quickly. Stainless steel is is more appealing to the eye and can be use for decorative products.

Carbon Steel is stronger and more durable then stainless steel. Stainless steel can stand up to humidity better than high carbon steel. However contrary to popular belief stainless steel is not rust-proof.

But unless you are storing your scissors in a pool of water rust should be a no-show. Stainless steel will technically stay sharper this also depends on the angle of the cutting edge. Compared to low-carbon steel stainless steel offers a massive upgrade in strength hardness and most importantly corrosion resistance.

High carbon steel offers strength rivaling and sometimes exceeding stainless steel but is largely a niche material in the manufacturing world. High carbon steel on the other hand offers strength rivaling and sometimes exceeding stainless steel but is essentially a distinct segment material within the manufacturing world. Unlike any carbon steel chrome steel can survive and thrive oxidation free in corrosive or humid environments.

Stainless Steel vs High-Carbon Steel Swords. One of the most influential elements in determining the quality of a sword is the metal used in its construction. Both bronze and iron for instance are relatively weak when compared to steel.

Some of the early Korean and Japanese swords made of bronze and iron were. Density of Stainless Steel vs Carbon Steel Density of typical stainless steel is 80 gcm 3 304 steel. Density of typical steel is 805 gcm 3.

Density is defined as the mass per unit volume. Stainless Steel vs Carbon Steel. Rusting Corrosion Resistance The main difference between stainless steel and carbon steel is obviously the corrosion resistance.

Stainless Steel is manufactured to resist rusting or corrosion. Among the two metals Stainless Steel is. As the carbon percentage rises the steel becomes harder and stronger but also less ductile meaning it is more likely to crack then bend when placed under high tensile stress.

Unlike stainless steel carbon steel is much more susceptible to rust and corrosion making the metal more difficult to maintain in hydraulic applications and wet environments. Chromium also has a high melting point. This is also why the stainless steel knife is more rust-resistant.

This also means that the stainless steel knife will last you for a much longer time than a carbon steel knife. But of course there are always downsides. Stainless steel knives are more malleable and springy and arent very brittle.

Carbon Steel an alloy of steel and carbon gets corroded but it is hard the more carbon content the harder the steel. Low-carbon steel is strong and tough and can be case-hardened if needed. High-carbon steel can be heat treated to make it a lot harder however in this condition it tends to be more brittle and more difficult to work with.

Though susceptible to rust unlike stainless steel carbon steel is often cheaper and has its own varying mechanical properties based on carbon content. Low-carbon steels are weaker and softer but can be machined and welded easily. While high-carbon steel is stronger but significantly harder to process.

Due to its low carbon content most stainless steel is somewhat softer than carbon steel and thus has a fairly low yield strength. This means that its more vulnerable to denting and bending than carbon steel. Most carbon steel on the other hand is somewhat brittleit has a relatively high yield strength but lower tensile strength.

Though more and more often youll hear the term High-Carbon Stainless which is a correct terms and refers to stainless steels with high Carbon content above 1. Although some manufacturers cheat and label knives with 07-08 Carbon as high Carbon since there is no law for it I guess. The pros of high carbon steel is they are much harder and sharper than stainless steel.

Making stainless requires adding 12 or more chromium. The added chromium in the stainless steel means less carbon. More carbon extra hardness.

However as you are aware high carbon steel has a lot more maintenance. Carbon steel is the more common high-volume steel in production which is used extensively in industries. Stainless steel has more ornamental and aesthetic appeal and finds uses in.

The amount of carbon can be as much as 12 and as low as 02. The reasons for this vary with the manufacturer and the type of blade theyre creating. High carbon stainless steel knives are resistant to rust or staining.

Stainless steel is an alloy that contains 105 or. Home chefs often choose stainless knives. Professionals often choose high-carbon steel.

Stainless knives are more commonly available and are easy to store. Martensitic stainless steels are generally used for cutting edges. These stainless steels are.

Stainless steels and high alloy tool steels are much more difficult to forge because they have high hot hardness difficult to move under the hammer cannot be annealed easily for grinding and working without temperature-controlled furnaces and have much more tendency to crack during forging or cooling from high temperature.