Dry aging beef isnt as simple as placing a steak on a plate and letting it sit in the fridge for a few weeks. Humidity control humicontrol only the dryager dry aging fridge does work 100 without external water supply or humidifier water box.

Dry aged beef is placed in an aging cooler with a controlled temperature between 35-38 and humidity of 50-60.

Humidity level for dry aging beef. Temperature relative humidity air movement and general sanitation of the aging room are essential considerations in successfully aging beef. Temperature of the aging room should be maintained at approximately 34 to 36 degrees Fahrenheit relative humidity at 85 to 90 percent and an air flow of 15 to 20 linear feet per minute at the surface of the product. Eff ects of Relative Humidity on Meat Quality in Dry Aged Beef Felipe A.

Bland Jeyamkondan Subbiah Chris R. Calkins Summary with Implications During dry- aging water is transferred from the interior to the meat surface and is subsequently evaporated to the surrounding environment. Th ere is a common belief in the meat.

80-85 It is possible to vary the humidity easily between 60-90. This slightly changes the flavor which makes the final product more individual. At higher values however the possibility of mold attack increases.

At low levels the outer crust dries deeper and deeper. In both cases more of the finished product has to be cut which results in a loss of the self-weight of 30-40. Effects of different relative humidity levels on dry-aged beef and it appears the studies in this area have used a relative humidity of approximately 80 with a considerable range around that number.

PALATABILITy ATTrIBUTeS flAvoR The greatest reason for dry aging beef is to further enhance its flavor and to impart. Literature reports the approximate value of 80 with a considerable range around it Dashdorj et al 2016. Lastly the humidity is important and it must be between 80 and 85.

At high levels of humidity mould growth is an issue. If the humidity is too low the beef will dry out too quickly and therefore cause the steak to have less juiciness than is needed Fig. A temperature of two degrees and 85 humidity is considered as optimal conditions for the dry aging.

To create the ideal climate however is not so simple. The second hurdle is constancy. Because the conditions should not change during the maturation process which can take up to 8 weeks.

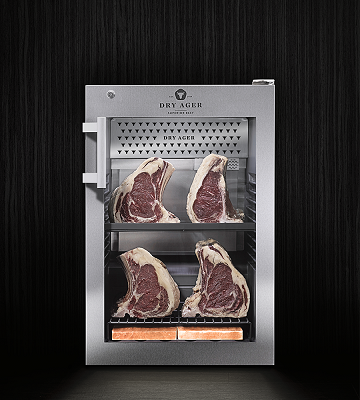

A modern drying cabinet such as the Dry Ager has been developed precisely for this problem. Temperature and humidity can be precisely regulated and controlled. For this the Dry Ager.

Dry aged beef is placed in an aging cooler with a controlled temperature between 35-38 and humidity of 50-60. This enables the natural enzymes of the beef to break down the muscle fibers thus tenderizing the meat. When dry aging beef the outside becomes stiff and there is a loss of moisture of up to 40 percent after trimming.

Dry aging works by exposing beef to a carefully controlled environment with specific temperature and humidity levels. In addition to an increase in tenderness bacteria activity enzymes oxidation and water loss tend to concentrate the flavor of the beef during this process. GUIDELINES FOR THE SAFE PRODUCTION OF DRY AGED MEAT Meat Livestock Australia Guidelines for the safe production of dry aged meat 7 What you need to do after reading these guidelines Review your work instructions or monitoring forms only you can do this for your individual operation and for approval by your controlling authority.

Dry aging is the process where beef carcasses or primal cuts are hanged and aged for 28 to 55 d under controlling environment conditions in a refrigerated room with 0 to 4 C and with relative humidity of 75 to 80. However there are various opinions on dry aging procedures and purveyors of such products are passionate about their programs. Recently there has been an increased interest in.

Dry aging bag has been tested for factors like temperature relative humidity air flow and microbiological activities involved in optimum beef dry. Humidity control humicontrol only the dryager dry aging fridge does work 100 without external water supply or humidifier water box. We generally go at least a week but usually not more than two i live in colorado which is a dry.

To ensure full exposure to the air do not stack the subprimals while dry-aging. Combined trimming and moisture loss from dry-aging can range from 15 to 25. Cold chain management is vital to preserve the safety and quality of the meat product.

This means that the temperature must be near the freezing point and the humidity level shall amount to about 60 per cent at all times. Beef is matured on the bone. Rib eye and sirloin steak take about 21 to 28 days the period for tenderloin only amounts to seven days.

In the process of dry aging the meat loses up to 40 per cent of its weight. Dry Aging is a unique and complex process that requires very specific temperatures and humidity levels to achieve the best possible outcome. As companies are dealing with raw meat products this long and drawn-out process can result in dangerous bacterial growth if strict procedures and conditions are not adhered to.

Once Dry-Aged meat is in storage and waiting to be distributed. Dry aging is the process where beef carcasses or primal cuts are hanged and aged for 28 to 55 d under controlling environment conditions in a refrigerated room with 0 to 4 C and with relative. Dry aging beef isnt as simple as placing a steak on a plate and letting it sit in the fridge for a few weeks.

You will need to invest in a few tools in order to do it properly. The first thing youll need is a dedicated refrigerator thats capable of holding 36F. Sure you can use the refrigerator in your kitchen but as Steven Raichlen points out its not.

Dry Aged Storage Temperature. Once a piece of beef has been selected as adequate for dry aging the beef is hung in a refrigerated room with temperatures maintained between 32 and 39 degrees Fahrenheit or 0 to 4 degrees Celsius and humidity is controlled to ensure freshness. The preferred humidity setting varies from 50 85 according to individual preference but usually is set closer to 60.

Beef in a dry-aging cabinet in a grocery store in Texas. You can see how the edges have dried and darkened. Dry aging Rather than storing the beef in vacuum packages dry-aged beef is aged without packaging in a specialized cooler or cabinet.

The temperature and humidity are closely controlled. It is usually a dark room or lit with special UV lights that help control microbial growth.