The product may be heated to higher temperatures and held for longer periods of time. Exposure time 1 m 9.

In the 1950s the minimum pasteurization temperature was.

Pasteurization temperature time chart. 160 degrees F for at least 6 seconds 165 degrees F for at least 28 seconds 170 degrees F for at least 13 seconds 175 degrees F for at least 06 seconds or 180 degrees F for at least 03 seconds 717 degrees C 161 degrees F for 15 seconds milk pasteurization is also considered adequate. Remember to set your Operational Limit higher to assure you meet your Critical Limit. The complete section on validation of.

Milk is deemed pasteurized if it tests negative for alkaline phosphatase. Frozen dairy dessert mix ice cream or ice milk egg nog. At least 69 C for not less than 30 min.

At least 80 C for not less than 25 sec. Other time temperature combinations must be approved eg. Temperatures less than 194F 90C and z 18F 10C for temperatures above 194F 90C.

Blue crabmeat pasteurized to a minimum cumulative total lethality of F. A minimum time-temperature combination for the pasteurisation of milk. 628oC 145oF for 30 minutes now known as the batch or holder method.

This heat treatment was slightly above what many people at the time considered to be adequate exposure for the destruction of. High temperature short time Pasteurization HTST The original method of pasteurization was vat pasteurization which heats milk or other liquid ingredients in a large tank for at least 30 minutes. It is now used primarily in the dairy industry for preparing milk for making starter cultures in the processing of cheese yogurt buttermilk and for pasteurizing some ice cream mixes.

Exposure times at internal temperatures above 50F 10C should be limited to 4 hours as long as no more than 2 of those OR If at any time the product is held at internal. Milk pasteurization was design to provide a minimum temperature and time combination needed to inactivate the most heat-resistant non-spore-forming disease causing organisms commonly associated with raw milk. Initially the target organism was the bacterium that caused tuberculosis Mycobacterium bovis or M.

In the 1950s the minimum pasteurization temperature was. In ultra-high-temperature UHT pasteurization milk is pasteurized at 135 C 275 F for 12 seconds which provides the same level of safety but along with the packaging extends. For example milk pasteurization historically was based on Mycobacterium tuberculosis and Coxiella burnetti but with the recognition of each new pathogen the required time temperature relationships are continuously being examined.

A thermal death curve for this process is shown below. It is a logarithmic process meaning that in a given time. B Pasteurizing operations.

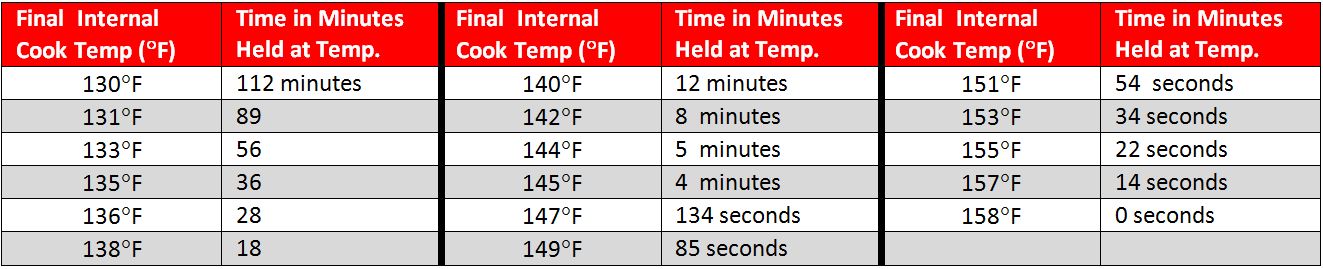

Every particle of all products must be rapidly heated to the required temperature and held at that temperature for the required minimum holding time as set forth in this section. The temperatures and holding times listed in Table I of this section are minimum. The product may be heated to higher temperatures and held for longer periods of time.

Pasteurization procedures shall assure complete pasteurization. Products are preheated to pasteurization temperature before entering the vat the recording chart shall show a holding period of at least thirty 30 minutes at not less than the minimum pasteurization temperature plus the time of filling from the level of the recording thermometer bulb. When cooling is begun in the batch pasteurizer after opening the outlet.

The word pasteurization was originally named after the French scientist Louis Pasteur who invented the process of heating liquids wine and beer at a relatively mild tempera-ture about 55 C for a short time to prevent spoilage Silva et al 2014. This quick heat method was. In high-temperature short-time HTST pasteurization the product is heated to the minimum temperature and held continuously at or above that temperature for at least the minimum time required.

Compared to vat pasteurization the required temperatures are much higher and the holding periods much shorter. Timetemperature or a surface timetemperature but the time temperature treatment to be achieved in the slowest heating part of the product. The latter is defined in EC 8522004 Annex II Chapter XI.

Within this report low temperature cooking is defined as any process where the maximum temperature attained during the process in the slowest heating part of the product is below 70ºC. The parameters for pasteurization in the United States fall under The Pasteurized Milk Ordinance PMO a cooperative effort of industry and state regulatory agencies in conjunction with the Food and Drug Administration. For white fluid milk the time-temperature relationship for HTST processed milk is a minimum of 161.

Smooth Hard Surface 14. Sterilization procedures and times for smooth surfaces. Exposure time 12-30 m at 20C 23.

Exposure time 1 m 9. Temperature Time The recording temperature chart is the official 145F 30 minutes. If the fat content of the milk product is 10 or more or if it contains added sweeteners the specified temperature would be increased by 5F.

So for a vat pasteurizer the temperature would be increased to 150F. There is a special temperaturetime requirement for the pasteurization of frozen dessert mixes. Pasteurization temperature control consists of recording the information shown on the circular chart figure on the next page and implementing the following strategies.

The first analog input is hot water temperature if Digital Reference Temperature option is selected then Input 3 is the Hot Water Temperature.